What sparked my interest in interning at Knitwin was when I happened to come across an episode of the TV show [Ohayou Asadesu] where news announcer Ayaka Sawada visitited Nara’s sock companies.

I had always liked socks, so naturally, I found myself visiting their shop to see what it was all about.

I remember feeling a kind of excitement that I have never felt before when I walked in and saw the socks on display.

When I felt them with my hands, I was very much impressed with the quality and texture and wanted to know what company created them.

I took a look at their website and was deeply impressed that the company Knitwin had stories behind each product.

Additionally, they were a factory brand that had expanded sales globally which made me more interested in applying for an internship there.

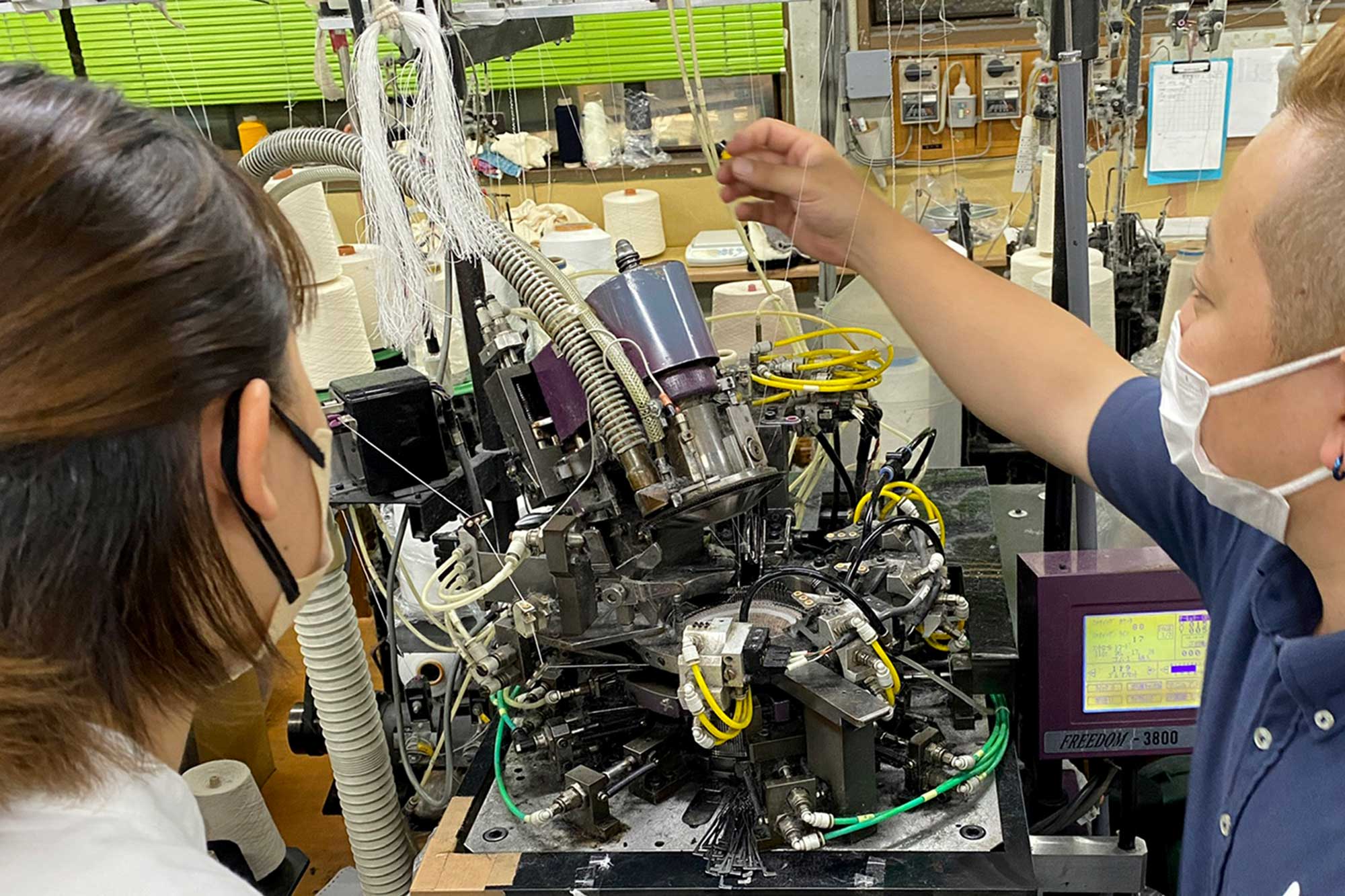

Within two months, I learned about the manufacturing processes, customer service, and store sales as well as attended exhibitions. I gained so much knowledge and experience which allowed me to appreciate products more because I saw the process in which they were created from start to completion. At the processing plant, I connected with the craftsmen. At the shop and exhibits, I saw first hand the manufacturing processes at Nara’s factories. Now I am always mindful of how a product got to the store shelf.

What I felt most was that everyone in the company had the same goal towards their products; the goal to work together, to create and deliver high-quality goods.

Additionally, my view of manufacturing goods changed significantly. More specifically, I now appreciate the value of manufacturing. The many hands that helped shape the product, the detailed concepts embedded, and the steps until completion. There is so much work put into a product before it reaches store shelves and now I hold more value and respect towards products.

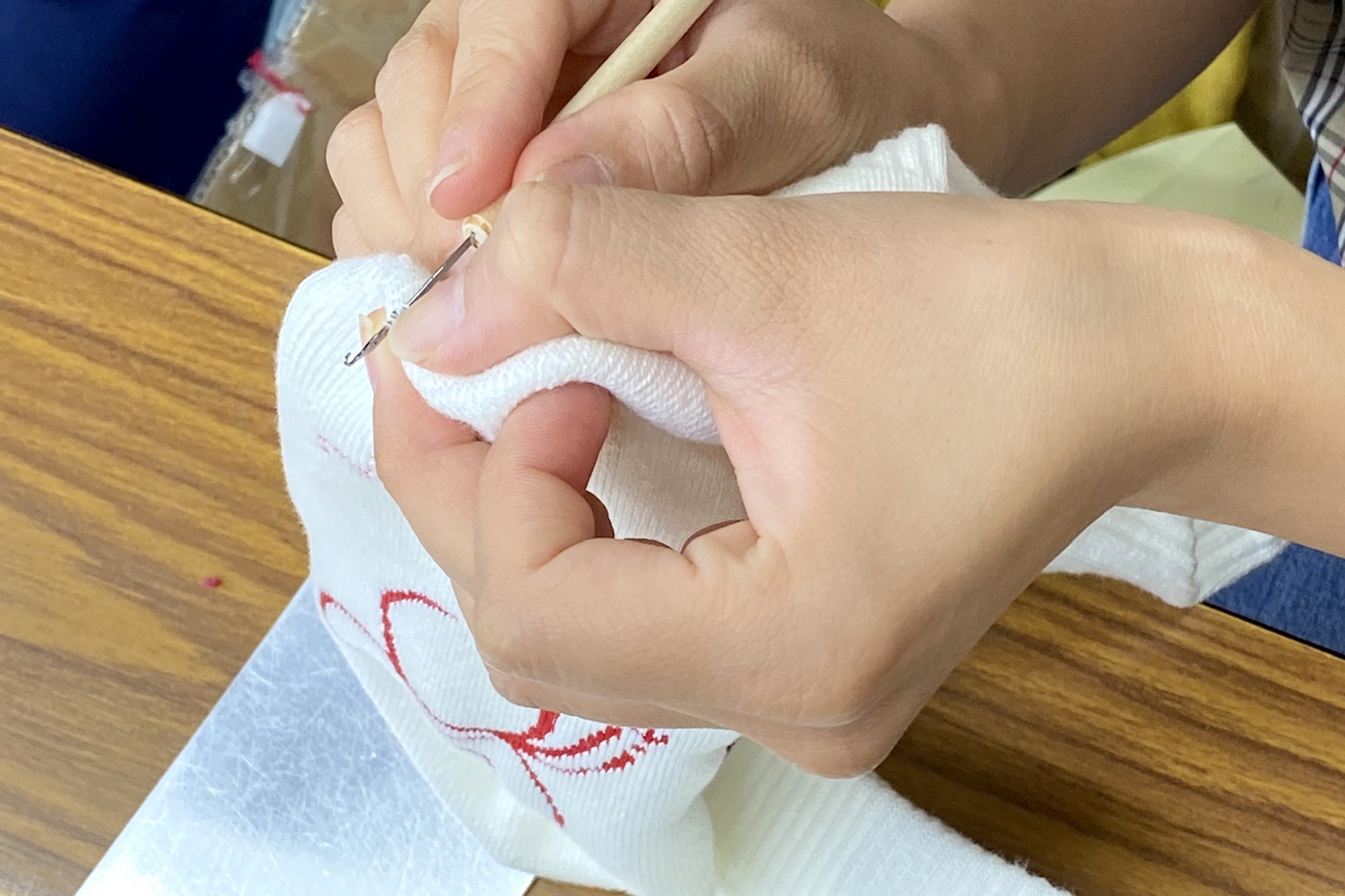

I was very much impressed at how each woven item was carefully inspected and processed. Staff would use their hands and other tools to inspect for any flaws and try to catch them at an early stage. They also took at least two months to inspect in various stages from completion to packaging so that customers only receive the finest pieces.

This vigorous process reduced B quality products and maintained high standards for high quality goods.

Additionally, I realized that during any part of the manufacturing process, staff asked questions to craftsmen when in doubt, and the environment was such that all staff were involved from start to finish, always sharing their thoughts with one another. I felt that the products were made with the shared ideas of staff from all levels.

I believe that the experiences gained from interning at a factory brand such as Knitwin will provide a boost to my career path.

Understanding each company’s unique ways provides many perspectives.

I haven’t decided what type of company/business I want to work for, however this internship allowed me to connect with people in various professions and learn about their different roles and perspectives so I think I was able to definitely broaden my perspectives on things.

I also had many opportunities to meet new people and hear their stories.

Although it is difficult to make time with people who are working, I was still able to get real advice and opinions from them which stimulated me to work on finding my own career path.

These 2 months were filled with new experiences. It all started with my email asking if they offered internships. They responded right away and made time out of their busy schedule for me. One staff told me to continue to speak up and work towards reaching my goals and I plan to do just that.

My experience at Knitwin will help shape who I am todaand help to enhance and broaden my career path.

Text/Aki Tanaka